Every element of the Titan, from its basic shape to the materials used, seemed destined to fail.

The recent catastrophic implosion of the Titan, the submersible famously used for Titanic tours, has exposed a multitude of design and build quality issues that go beyond the well-known problems associated with its wireless game controller and lights sourced from Camping World. While OceanGate CEO Stockton Rush was remarkably adept at convincing people of the sub's safety, a closer examination reveals fundamental and fatal flaws in its design.

One of the most glaring issues lies in the shape of the Titan's cabin. While OceanGate Expeditions boasted about the sub's roomier, cylinder-shaped carbon-fiber cabin, industry experts argue that this departure from the sphere-shaped cabins made of titanium, commonly found in most submersibles, was a critical misstep. A sphere is considered a "perfect shape" because it distributes water pressure equally across all areas. Chris Roman, a professor at the University of Rhode Island's Graduate School of Oceanography, explains that the Titan's larger internal volume, although still cramped with a maximum capacity of five seated people, subjected it to greater external pressure due to its non-spherical design.

However, the issues with the Titan extend far beyond its shape. A comprehensive analysis conducted by an engineer experienced in testing vessels in deep-sea environments sheds light on numerous alarming concerns. One of the focal points of criticism is the untested carbon fiber hull. While carbon fiber is renowned for its strength, it is also known to be vulnerable to damage and strain. This raises doubts about its suitability for deep-sea exploration. In contrast, most deep-sea vessels are constructed using steel or titanium, materials that offer greater homogeneity when manufactured correctly, thereby reducing the risk of failure.

Another worrisome aspect highlighted in the analysis is the method used to attach the carbon fiber tube to two hemispheres made of titanium. OceanGate opted for epoxy to affix the two materials, which introduces a new set of challenges and potential failure points. The epoxy is subjected to different types of stress from the carbon fiber and titanium, increasing the likelihood of structural weaknesses. The video points out that the application of the epoxy, as depicted in a video released by OceanGate, was performed in a less-than-ideal environment—an open warehouse lacking the necessary controlled conditions for such a critical installation.

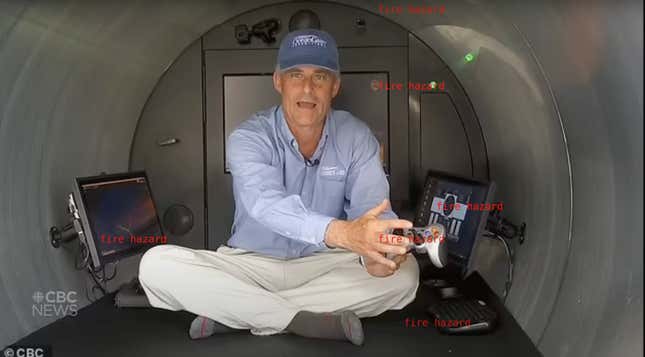

Furthermore, the video delves into the alarming safety risks associated with the off-the-shelf electronics used in the Titan. These components were found to pose unacceptable fire hazards, raising serious concerns about the sub's overall safety standards. Additionally, the absence of passenger restraints for both the pilot and passengers further compounds the potential dangers. Exposed tubing on the exterior of the craft adds another layer of vulnerability, increasing the likelihood of disaster.

Moreover, the depth-worthiness of the viewing port is called into question. Despite the sub routinely venturing to depths of 4,000 meters, the viewing port was only certified for a depth of 1,300 meters, as reported by NPR. This discrepancy raises concerns about the sub's structural integrity and its ability to withstand the immense pressure at greater depths.

In summary, the detailed breakdown of the Titan submersible highlights how seemingly minor technical glitches and design choices can have dire consequences. The flaws in its shape, the untested carbon fiber hull, the questionable epoxy bonding, the fire risks associated with off-the-shelf electronics, the lack of passenger restraints, the exposed tubing, and the inadequate depth certification of the viewing port all contribute to a picture of compromised safety. This analysis underscores the critical need for rigorous engineering practices, meticulous attention to detail, and thorough testing to ensure the safety and reliability of deep-sea exploration vessels.