Ever notice those weird, brightly colored lines under the hood of a new car and think the assembly-line robot must have had a little too much fun with the paint pens? Well, those yellow and blue — and sometimes other colors of the rainbow — marks aren't a sign of a party at the factory. They're a silent language that tells a story of quality, precision, and safety.

These marks are a crucial part of the quality control system carmakers rely on. Think of them as a factory worker's version of a checklist. A quick swipe of a marker can mean a bolt has been tightened to the exact right spec, a part has passed inspection, or a component is installed in the correct orientation. They're a high-speed, low-tech solution, ensuring that all the hands building your car did it the proper way. So understanding the purpose of those yellow and blue squiggles gives you a peek into the attention to detail that goes into building a car.

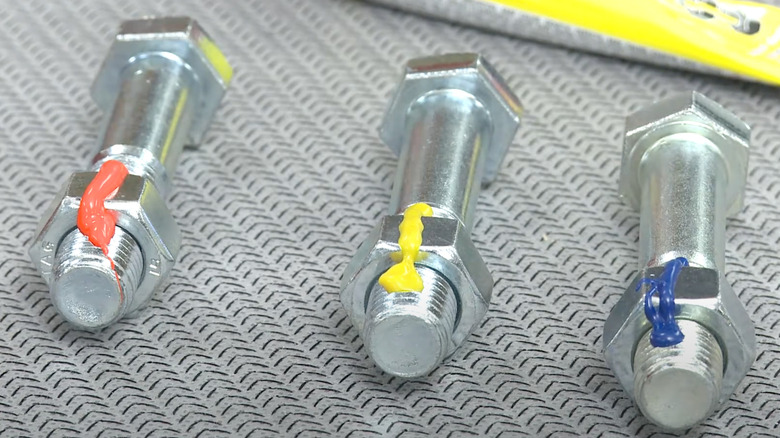

To understand what these marks mean, you have to know there's a hierarchy. The most basic type is something called a witness mark, a simple line drawn across a nut or bolt and the surface it's tightened against. If that line ever breaks, it's an immediate visual sign that the fastener has loosened, a trick used everywhere from firearms to race cars.

But the automotive world takes it a step further with something called Torque Seal, a brittle industrial paste applied to critical fasteners after they've been torqued to spec. Once this paste cures, it's designed to crack if the bolt moves even a tiny bit, providing an instant impossible-to-miss signal of a possible problem. Torque Seal is also common at quickie lube spots, used to prevent fraudsters from dumping oil and then blaming the tech who performed the service.

But what about the colors? Here's the part that might be a little disappointing: the colors themselves don't have a universal industry-wide meaning — at least from any readily available common knowledge. There's no secret decoder ring that says yellow is for suspension bolts or blue is for brake calipers. The main goal is just visibility — picking a color that stands out against the part it's marking. Within a single factory, however, the colors are likely part of an internal system.

For the average car owner, these little marks are a good thing. They're a sign of a thoughtfully assembled and checked-over vehicle, not a defect to be scrubbed off during your first wash. With humans still on the assembly lines — at least for the foreseeable future — these checks and balances are a good sign.

But for the aspiring DIY mechanic, they serve as both a guide and a warning. If you ever have to loosen a bolt with Torque Seal on it — say, on your brakes or suspension — you should never simply tighten it back until the old lines match. That's a great way to undertighten or overtighten a critical part, which could have catastrophic results.

The original mark is there to show it was torqued correctly the first time. Once you break that seal, the only way to do the job right is to use a calibrated torque wrench and tighten the fastener to the manufacturer's exact spec, something any decent Jalopnik reader should already know — but still worth the callout. As we all know, some car repairs you should just be able to do yourself. If you want to be extra professional, you can even buy your own Torque Seal paste, paint pen, or grease pencil, and apply a new witness mark after you're done.