By the middle of 1938, Europe had begun inching toward destruction. Adolf Hitler had taken over Austria, the beginning of Germany's bloody campaign that would pull the continent into the chaos of World War II. Across the Atlantic, U.S. President Franklin D. Roosevelt understood the need for the American military to be prepared for the coming war, something the country had failed to do before World War I. He petitioned Congress for 10,000 new airplanes, a big ask given that the country was still in the throes of the Great Depression, and nowhere near the military powerhouse it is today. Its Army Air Corps ranked even lower, with a meager arsenal of outdated planes.

Congress reached a compromise, approving just over half of the requested number of planes to be built over the next five years. However, the tide of war was in Germany's favor, and by 1940, the Nazis had conquered Belgium, France, the Netherlands, and Luxembourg. It was only a matter of time before the U.S. would be drawn into the war, which happened in December 1941, when Germany's ally Japan attacked Pearl Harbor. Knowing this threat, Roosevelt pushed Congress again, this time asking for 50,000 planes a year. The task seemed impossible to many, but by 1944, America was churning out nearly twice that amount of bombers every year.

Heritage Images/Getty Images

Heritage Images/Getty Images

Roosevelt achieved this feat by turning to an industry known to produce complex machinery on a large scale. Automakers are known for their engineering expertise and ability to produce a large number of components in a short time. Car companies took to building bombers and weapons. The B-24 Liberator became the go-to plane due to its long-range ability, making it a formidable asset to deal with enemy forces across the Pacific Ocean, as well as Britain's affinity for the heavy bomber in the fight against Germany.

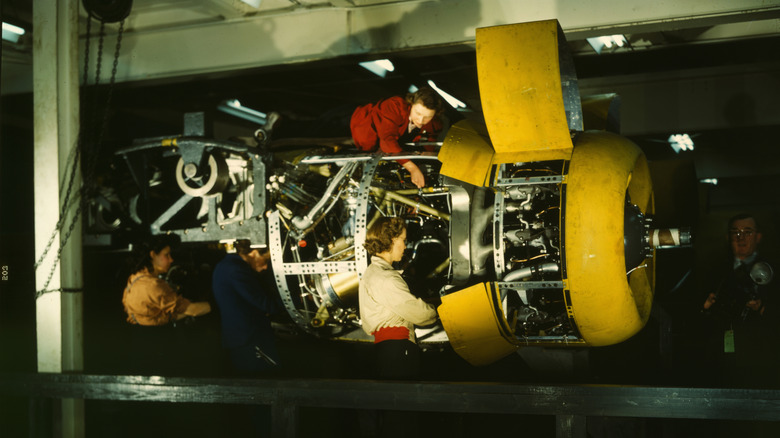

Consolidated Aircraft held the contract to build B-24 bombers, but its output was anything but efficient (read painfully slow). The company built aircraft outdoors on makeshift rigs where workers spent hours attaching a single engine.

Ford was one of the carmakers approached to make parts for the B-24. In early 1941, Ford executive Charles Sorensen visited the Consolidated factory and was appalled by what he saw. Highly experienced in the field of production and assembly, Sorensen sketched a production line for the B-24 that night by breaking down the massive bomber into sub-assemblies that could be built like cars on a moving production line. Ford decided to be more involved. It declared that it would not build B-24 bomber parts; it would build the entire B-24.

Archive Photos/Getty Images

Archive Photos/Getty Images

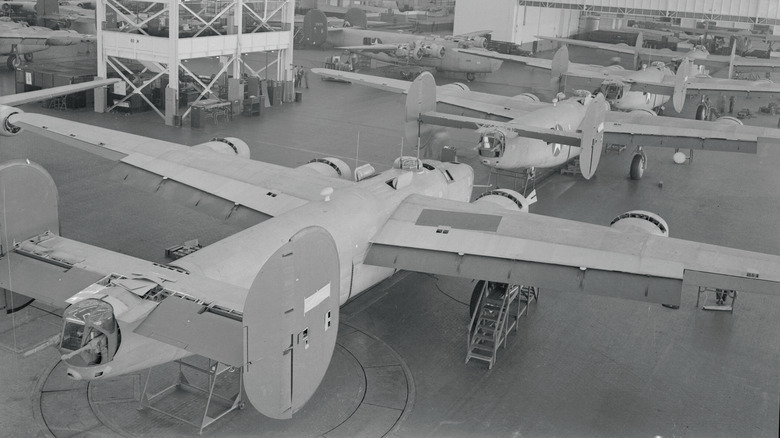

In February 1941, the Army awarded Ford a contract to build B-24 planes, and the carmaker began construction of a massive production complex west of its home base in Detroit. The Willow Run plant grew to become the world's largest factory at the time. It featured an unusual 90-degree turn, giving it a unique L-shaped layout. It solved two problems — avoiding stretching into a planned airport and having the entire facility inside one county, which helped save on taxes.

By late 1941, and $47 million later, the Willow Run factory was operational. It was expensive, but not as expensive as a $90-million F-35 fighter jet crashing straight out of the factory. Ford even built an adjoining airfield so that the bombers, fresh off the assembly line, could be tested for fitness on the runway before being sent to war. Having a Short SC1 vertical-takeoff fighter jet that didn't need a runway would have surely saved Ford money.

To give you a scale of the operation, a B-24 bomber is 66 feet, 4 inches long, with a wingspan of 110 feet. The Willow Run factory, meanwhile, spans 3.5 million square feet. To staff this mega factory, the government provided assistance by transporting and housing much of the workforce and their families.

Anthony Potter Collection/Getty Images

Anthony Potter Collection/Getty Images

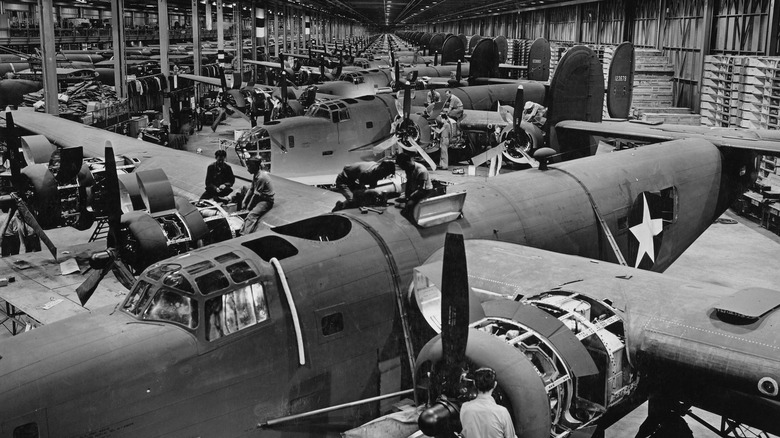

The Willow Run factory was a turning point for the aircraft-building industry. It was the first time that instead of a bomber plane being constructed in one place, it was built by sub-assemblies being mated together on an assembly that stretched for a mile. Construction saw fuselages, wings, and tail sections come together at critical junctions, taking the shape of a bomber as it moved forward. Initially, production was slow. However, as efficiency improved, production shot up as well. By 1944, Ford was making one bomber every 63 minutes. At its height, the Willow Run factory produced 428 bombers in a single month.

It wasn't easy, though. With no usable blueprints from Consolidated, Ford's engineers had to reverse-engineer thousands of bomber-part drawings before an assembly line could be set up. It came to a point where engineers were drawing up miles of technical schematics every day. Ford management had to navigate both the government and Consolidated Aircraft, which still held part of the original contract.

Constant design changes from Consolidated caused hurdles, while congressional investigators found that meddling from the original contractor was causing delays. Eventually, complete control of the plant was handed over to a single plant manager, and from then on, production began to stabilize. Once the red tape cleared, Ford's methods began to shine, and Willow Run became the most prolificAmerican factory during World War II.

Bettmann/Getty Images

Bettmann/Getty Images

The workforce at Willow Run became a symbol of America during the war. As men were conscripted for war, women filled their places on the assembly line. Thousands of women entered the workforce, taking on jobs like riveting and spot welding. While some sources dispute this, Ford says the iconic 'Rosie the Riveter' poster, which went on to symbolize women taking on traditional men's roles and become an iconic part of pop culture and the feminist movement, was inspired by Rose Will Monroe, a worker at the Willow Run plant.

People from all over the U.S. settled in Michigan, attracted by the promise of urban life and steady pay. Employment peaked at 42,000 before tapering off as production efficiency improved. Ford used every resource available to ramp up production. An example is using little people to climb inside the bomber's wings to hold parts in place.

The plant's sheer size meant that managing the workforce required unusual solutions. The Willow Run plant site had an on-site hospital and a recreational field, and hordes of buses ferried workers every day from Detroit and surrounding towns. Willow Run wasn't just an industrial experiment; it was a social one.

Bettmann/Getty Images

Bettmann/Getty Images

By the end of World War II, the Willow Run factory had produced over 8,600 B-24 bombers. Production stopped a few months before the war ended in August 1945, but the B-24 already was on its last legs before that.

By 1943, the U.S. military had already started testing its new B-29 Superfortress, which offered a long range, could carry a bigger payload, and fly higher in the atmosphere as well, thanks to a pressurized cabin. For the time, it probably had a cockpit as cool as the one on the F-22 Raptor fighter jet. The B-29 was used to drop atomic bombs on the Japanese cities of Hiroshima and Nagasaki, leading to Japan's eventual surrender to the Allies.

The Willow Run factory was eventually sold off to other carmakers. Today, a portion of it serves as the Michigan Flight Museum. However, its legacy remains as the birthplace of mass-produced aircraft. The mile-long factory helped win World War II, one bomber at a time.