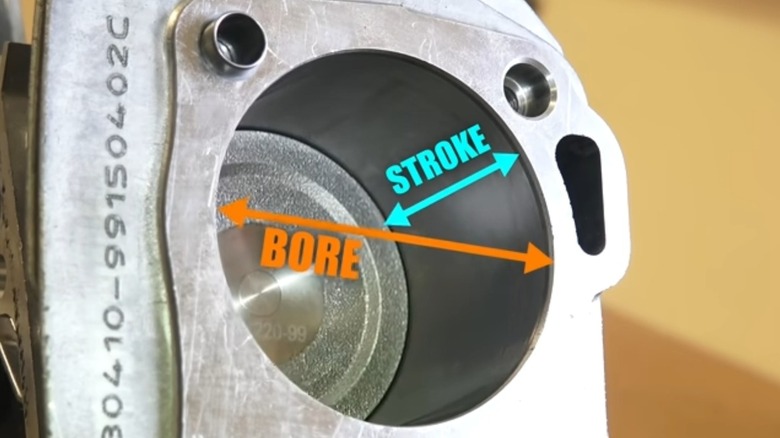

Gearheads and faithful Jalopnik readers already know the basics of an engine's bore and stroke, but for those that might be new here, let's dip our toes in the shallow end. An engine's bore refers to the diameter of its cylinders, while its stroke is the distance of the pistons from the top to the bottom of their travel. Stroke is controlled by eccentric offset — in other words, the distance between the crankshaft's rod journals to the centerline of the main journals. More offset equals longer stroke.

An engine's displacement is derived by a calculation where bore and stroke play pivotal roles. It involves finding the volume of one cylinder, then multiplying that with the number of cylinders. With all other specs being equal, engines with a larger displacement have more power than smaller ones, giving rise to the adage, "there's no replacement for displacement."

While automotive engineers have spent countless hours investigating the perfect bore-to-stroke ratio for their engines, many engine builders have taken matters into their own hands with creations like the Chevy small block 383 stroker. The 383 stroker uses a 0.030-inch oversize-bored Chevy 350 engine block, and the longer-stroke crankshaft of a 400 Chevy small block (3.75 inches compared to the 3.48-inch stroke of standard 350 crank). While the crankshaft needs some modification to fit into the block, the benefits of adding more stroke the 350, one of the most powerful Chevy small block engines ever, are worth it for some.

Sodel Vladyslav/Shutterstock

Sodel Vladyslav/Shutterstock

In our 383 stroker example, on top of the engine making more power due to its increased displacement, it also has increased torque thanks to the longer crankshaft stroke. As the crankshaft spins around its center axis secured by the engine block's main bearings, the connecting rod journals push the pistons toward the cylinder head for the compression stroke. Upon combustion, the piston pushes down on the crankshaft during the power stroke. The assumed advantage of a longer stroke is that it provides more leverage for the work being performed, giving the engine more torque.

An engine's torque is one factor that determines its horsepower, and revolutions per minute (rpm) is the other. Using the simplified version of the horsepower equation – Horsepower = Torque x rpm / 5,252 — we can see that between two engines with the same torque output, the one that revs higher has more horsepower. While rpm is limited by a number of factors, such as airflow, valve float, and piston speed, the latter is related to stroke length. A piston connected to a longer stroke crankshaft has to go faster to achieve the same rpm as a piston in a shorter stroke engine.

YouTuber Engineering Explained calculated the potential maximum rpm for theoretical engines with identical displacements but different bore-to-stroke ratios. Using the same average piston speed for reference, the 47mm-stroke example achieved nearly twice the rpm as the 86mm stroke version.

Now that we know how they affect rpm, we can see that engines with excessive stroke lengths aren't typically the way to go. This is seen when comparing bore-to-stroke ratios of some legendary naturally-aspirated horsepower mills from General Motors, Ford, and Mopar. They all used larger bores compared to the crankshaft stroke, which is a condition known widely as "oversquare."

A good example of how minor differences in bore-to-stroke ratio can affect performance is the comparison between the Chevy and Ford 400 cubic-inch small-block engines. While neither engine was designed with maximum horsepower in mind, the Chevy 400 was capable of more power from the factory. This was thanks, in part, to its oversquare ratio compared to Ford's perfectly-square approach.

In addition to horsepower's relationship to torque and rpm, the ability to get more air through the engine plays a role as well. Larger diameter cylinders can accommodate larger intake and exhaust valves, allowing more airflow through the engine. The desire for larger valves is one of the drivers behind cylinder heads with pent-roof and hemispherical combustion chambers, designs renowned for their power.